10 Best Leather Laser Engraving Machine 2026 in the United States

Winner

WECREAT Vision 40W Laser Engraver and Cutter Machine with Automatic Conveyor Feeder, Fume Extractor, 4-in-1 Rotary, Air Assist, Laser Bed for DIY Engraving and Cutting Acrylic Wood Metal Leather

The WECREAT Vision 40W Laser Engraver and Cutter Machine offers a powerful 40W laser, capable of easily cutting through 18mm wood and 15mm acrylic with a high speed of up to 600mm/s, making it suitable for efficient batch productivity. The large engraving area of 137'' x 14.9'' provides flexibility for handling large projects, which is a significant advantage for users dealing with substantial materials. Additionally, the machine boasts a highly effective smoke purifier, ensuring a cleaner and safer workspace, which is ideal for indoor use.

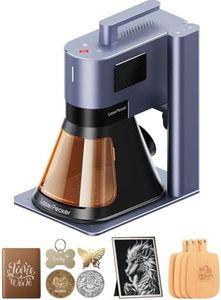

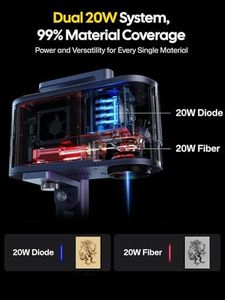

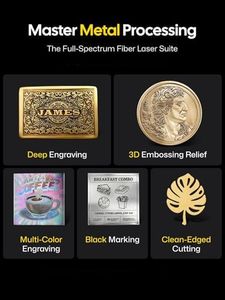

LaserPecker LP5 20W Fiber & Diode Dual Laser Engraver, 10X Faster 0.0027mm Precision for Metal Wood Jewelry, 3D Grayscale & Color Engraving, Portable 6kg Laser Cutter for Instant Store Customization

The LaserPecker LP5 is a versatile laser engraving machine well-suited for those looking to customize leather and other materials efficiently. One of its standout features is the impressive speed of 10,000mm/s, which significantly boosts productivity, making it a great choice for small businesses and creative studios needing quick turnaround times. The dual 20W laser system offers a remarkable precision of 0.0027mm, ensuring that intricate designs are rendered with clarity on various materials, including leather, wood, and metals. Its lightweight design enhances portability, allowing users to take it to craft shows, workshops, or retail locations easily.

Most important from

49 reviews

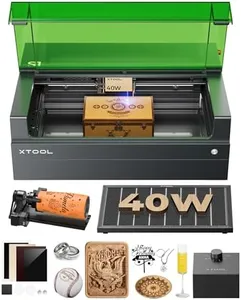

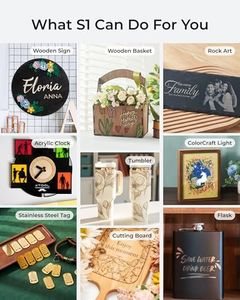

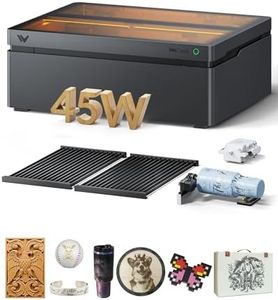

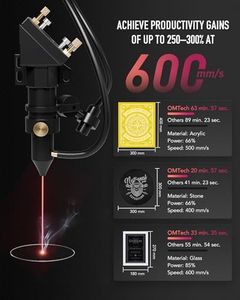

xTool S1 40W Laser Cutter and Laser Engraver for Tumblers, 23.93" x 15.16" Bed Size, 600mm/s Speed, Laser Engraving Machine, Laser Engraver for Wood and Metal, Acrylic, Big Project - Rotary Bundle

The xTool S1 40W Laser Cutter and Engraver is a robust machine designed for various engraving tasks, including on leather. Its powerful 40W laser can efficiently cut through materials like 18mm cherry wood, promising high productivity with its impressive speed of up to 600mm/s. The large engraving area of 23.93" x 15.16" makes it suitable for big projects, allowing users to work on multiple items simultaneously, such as up to 119 dog tags in one go.

Most important from

272 reviews

Top 10 Best Leather Laser Engraving Machine 2026 in the United States

Winner

WECREAT Vision 40W Laser Engraver and Cutter Machine with Automatic Conveyor Feeder, Fume Extractor, 4-in-1 Rotary, Air Assist, Laser Bed for DIY Engraving and Cutting Acrylic Wood Metal Leather

WECREAT Vision 40W Laser Engraver and Cutter Machine with Automatic Conveyor Feeder, Fume Extractor, 4-in-1 Rotary, Air Assist, Laser Bed for DIY Engraving and Cutting Acrylic Wood Metal Leather

Chosen by 1457 this week

LaserPecker LP5 20W Fiber & Diode Dual Laser Engraver, 10X Faster 0.0027mm Precision for Metal Wood Jewelry, 3D Grayscale & Color Engraving, Portable 6kg Laser Cutter for Instant Store Customization

LaserPecker LP5 20W Fiber & Diode Dual Laser Engraver, 10X Faster 0.0027mm Precision for Metal Wood Jewelry, 3D Grayscale & Color Engraving, Portable 6kg Laser Cutter for Instant Store Customization

xTool S1 40W Laser Cutter and Laser Engraver for Tumblers, 23.93" x 15.16" Bed Size, 600mm/s Speed, Laser Engraving Machine, Laser Engraver for Wood and Metal, Acrylic, Big Project - Rotary Bundle

xTool S1 40W Laser Cutter and Laser Engraver for Tumblers, 23.93" x 15.16" Bed Size, 600mm/s Speed, Laser Engraving Machine, Laser Engraver for Wood and Metal, Acrylic, Big Project - Rotary Bundle

xTool P2S 55W CO2 Laser Cutter, Smart Desktop CO2 Laser Engraver and Cutter Machine, Dual Smart 16MP Cameras, 3D Curved Cylinder Engraving, Create with Wood and Metal Acrylic Glass Fabric Leather

xTool P2S 55W CO2 Laser Cutter, Smart Desktop CO2 Laser Engraver and Cutter Machine, Dual Smart 16MP Cameras, 3D Curved Cylinder Engraving, Create with Wood and Metal Acrylic Glass Fabric Leather

xTool F1 2-in-1 Dual Laser Engraver, Lightning Speed Portable Laser Engraving Machine, HD Laser Engraver for Jewelry, Metal, Wood, Leather

xTool F1 2-in-1 Dual Laser Engraver, Lightning Speed Portable Laser Engraving Machine, HD Laser Engraver for Jewelry, Metal, Wood, Leather

LaserPecker LP4 (Ultimate) with Desktop Air Purifier, Dual-Laser Engraver Cutter 160x300mm Workspace, Auto-Cleaning Smoke Fumes Engrave Tumblers Metal Wood Plastic Glass with Slide & Rotary Extensions

LaserPecker LP4 (Ultimate) with Desktop Air Purifier, Dual-Laser Engraver Cutter 160x300mm Workspace, Auto-Cleaning Smoke Fumes Engrave Tumblers Metal Wood Plastic Glass with Slide & Rotary Extensions

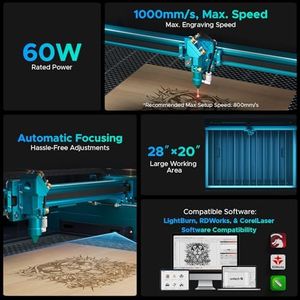

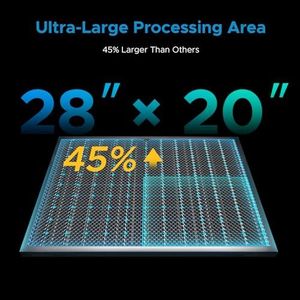

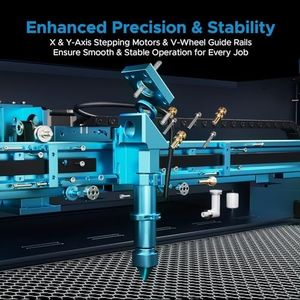

OMTech 60W CO2 Laser Engraver, 28x20 Inch Laser Engraving Cutting Machine with Autolift 4 Way Pass Air Assist Water Pump, Commercial Laser Engraver Cutter for Wood Glass Leather More

OMTech 60W CO2 Laser Engraver, 28x20 Inch Laser Engraving Cutting Machine with Autolift 4 Way Pass Air Assist Water Pump, Commercial Laser Engraver Cutter for Wood Glass Leather More

OMTech Pronto 35 60W CO2 Laser Engraver Cutter with Water Chiller, 28"x20" Autofocus Engraving Machine with Air Assist & 2-Way Pass-Through, Laser Cutter for Wood Acrylic Leather Glass

OMTech Pronto 35 60W CO2 Laser Engraver Cutter with Water Chiller, 28"x20" Autofocus Engraving Machine with Air Assist & 2-Way Pass-Through, Laser Cutter for Wood Acrylic Leather Glass

Algolaser 20W Laser Engraver Machine - Laser Cutter/Engraver with Air Assist Kit - Laser Engraving Machine with 3.5" Smart Touchscreen & 2.0 AlgoOS System, Laser Engraver for Wood,Metal,Glass

Algolaser 20W Laser Engraver Machine - Laser Cutter/Engraver with Air Assist Kit - Laser Engraving Machine with 3.5" Smart Touchscreen & 2.0 AlgoOS System, Laser Engraver for Wood,Metal,Glass

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.